News Center

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

-

2025-06-24

2025-06-24

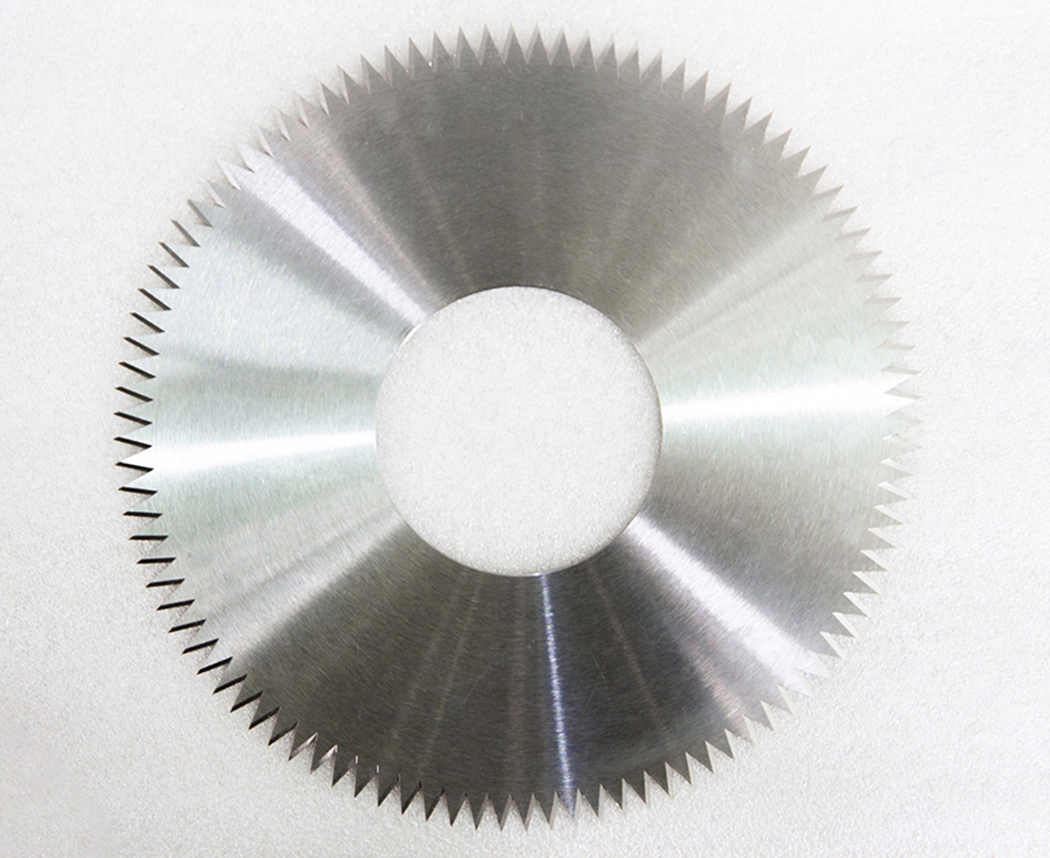

What is the function of high-speed steel sharp angle knife

High speed steel sharp angle cutter is a type of cutting tool made of High Speed Steel (HSS) material and designed with a sharp angle blade. Its unique material characteristics and geometric shape give it a clear functional positioning in the field of mechanical processing. Its main functions are as follows:

-

2025-06-17

2025-06-17

What are the advantages of flat edged round knives

The advantages of flat mouth circular knives vary depending on their application scenarios. The following will introduce them from common fields: 1. In the field of carving (such as woodcut and seal carving): Woodcarving: The blade is straight and can quickly remove the surface of wood. The large flat edged round blade is suitable for handling large blank areas, while the small one is used

-

10 06 2025

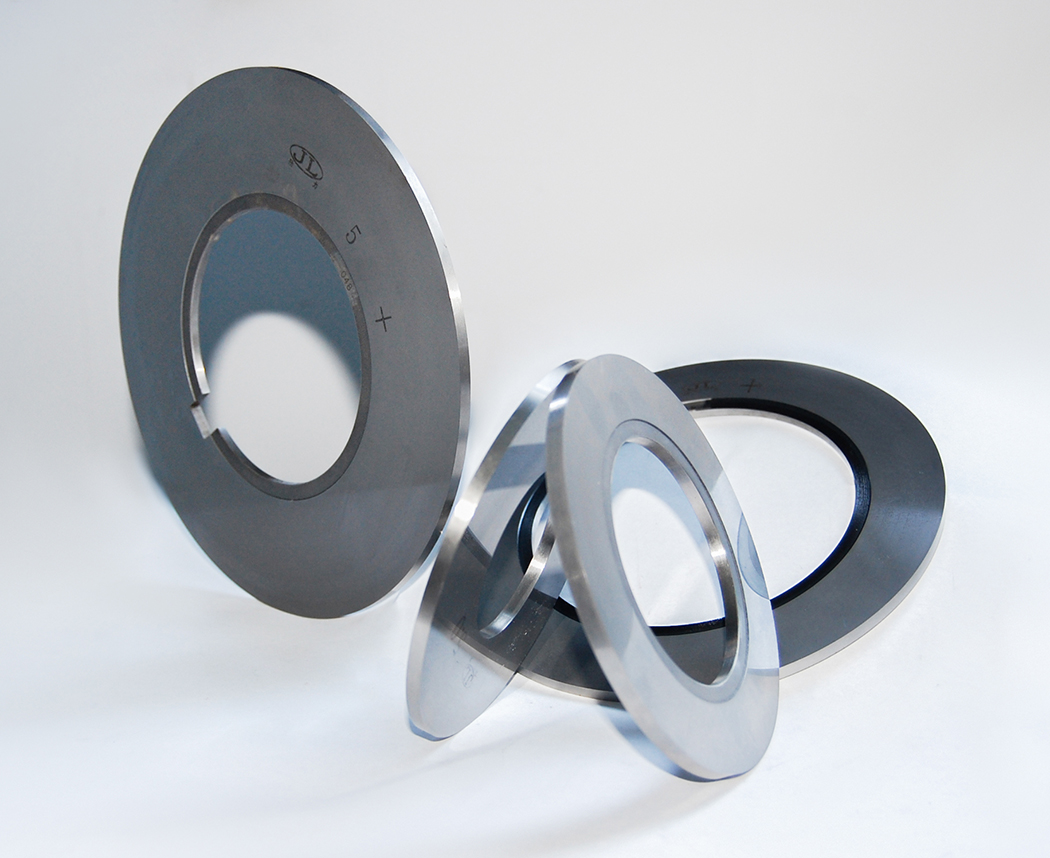

What are the applications of slitting circular knives in the paper industry

The slitting round knife is a key cutting tool used in the paper industry for paper slitting and cutting. Its high precision, wear resistance, and stability directly affect the processing quality and production efficiency of paper. The following are the main application scenarios and characteristics of slitting circular knives in the paper industry:

-

04 06 2025

In which industries are high-speed steel single angle milling cutters applied

High speed steel single angle milling cutter is a milling tool with a specific angle cutting edge, commonly used for machining various angle grooves, inclined surfaces, step surfaces and other features. It has a wide range of application industries, mainly including the following areas:

-

27 05 2025

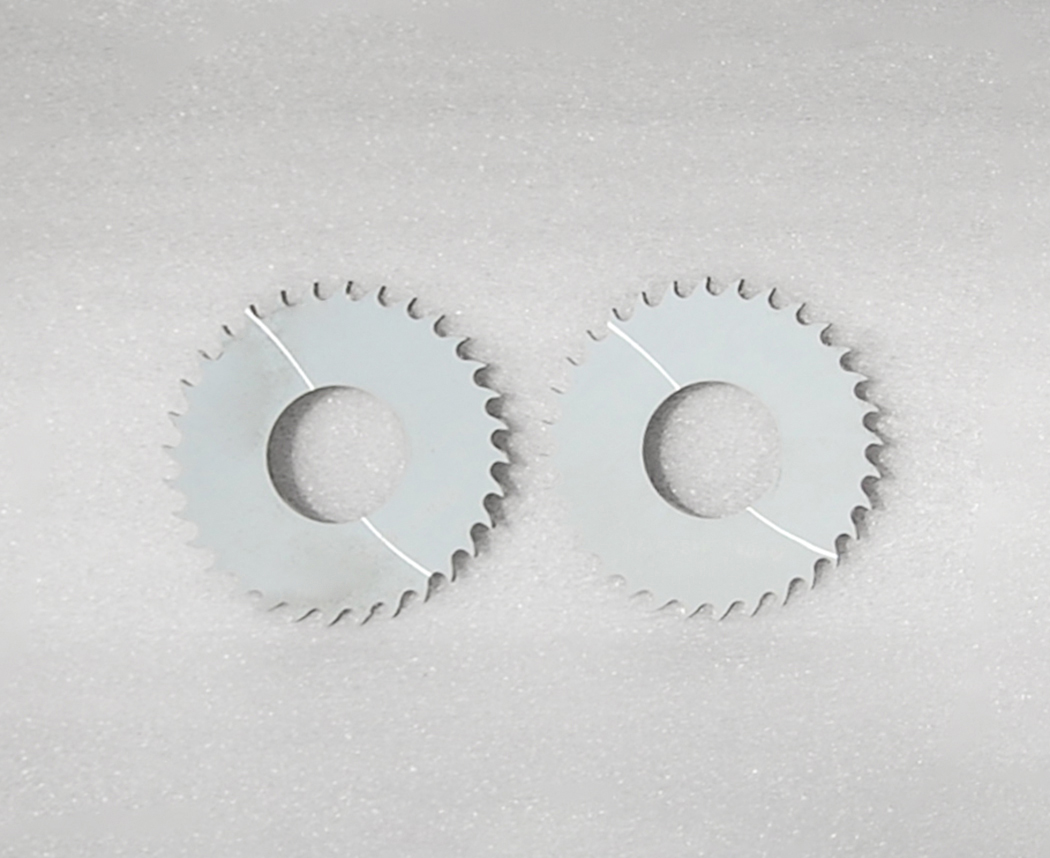

What are the characteristics of tungsten steel round fox teeth

Tungsten steel round fox teeth (usually referring to cutting tools or parts made of tungsten steel material with circular arc teeth, such as gears, milling cutters, saw blades, etc.) have the following characteristics, mainly derived from the material properties of tungsten steel (hard alloy) and the structural advantages of circular arc teeth: 1、 Core advantages brought by material properties 1

-

20 05 2025

What are the characteristics of tungsten steel angle knives

Tungsten steel angle cutter (also known as hard alloy angle cutter) is a cutting tool made of tungsten steel (hard alloy) material, mainly used for machining grooves, slopes, bevels or formed surfaces of various angles. Its core characteristics stem from the high hardness, wear resistance, and targeted design of tool structures of tungsten steel materials. The following is a specific analysis:

-

13 05 2025

Introduce the material characteristics of tungsten steel round fox milling cutter

The material characteristics of tungsten steel arc milling cutters mainly include the following aspects: 1. High hardness and strength Tungsten steel is an alloy composed of hard phases such as tungsten carbide (WC) and bonding phases such as cobalt (Co). Tungsten carbide has a high hardness, reaching HRA90-95, which is much higher than ordinary steel. This allows tungsten steel arc milli

-

06 05 2025

What is a high-speed steel angle milling cutter

High speed steel angle milling cutter is a cutting tool used in metal processing and other fields. The following is its detailed introduction: 1. Material: The entire cutting tool or the cutting head is made of high-speed steel material. High speed steel is an alloy tool steel with high hardness, wear resistance, and heat resistance, containing alloying elements such as tungsten, molybdenum, chro

-

28 04 2025

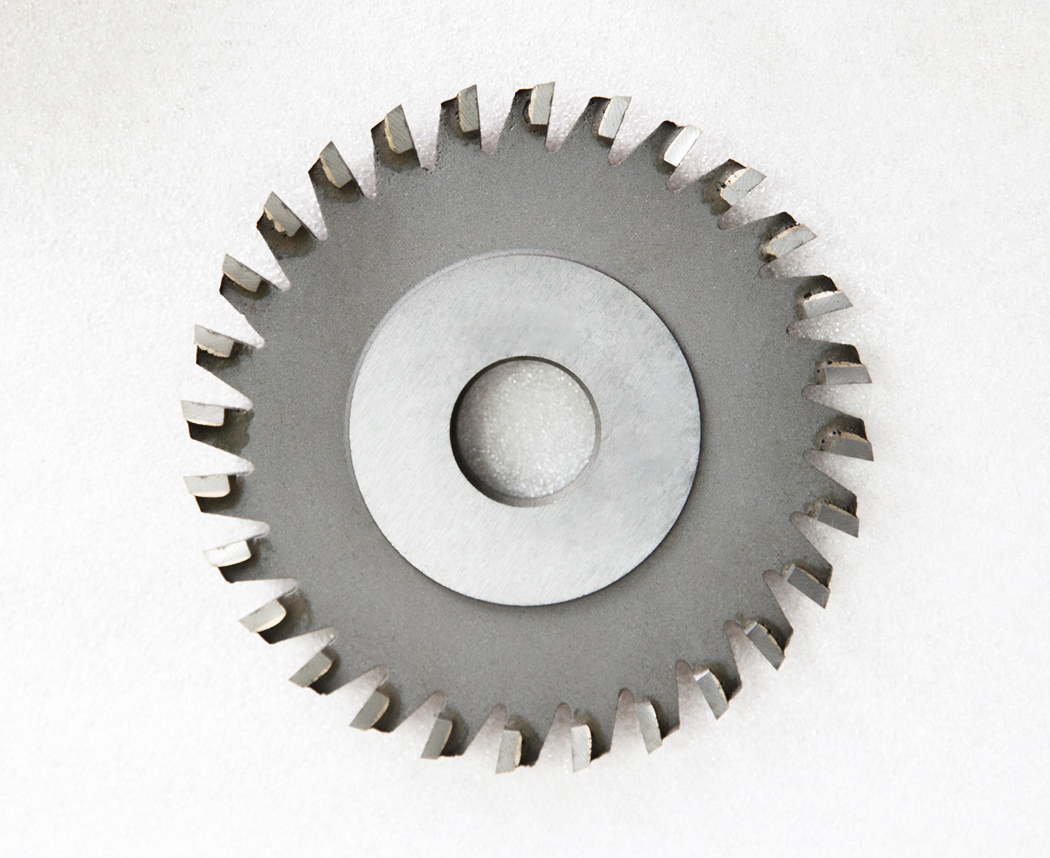

What are the main uses of three sided milling cutters with embedded teeth

A three sided milling cutter with embedded teeth is a commonly used milling tool, mainly used in the following aspects: 1. Processing step surface: In mechanical processing, it is often necessary to process various step structures of parts. The three sided milling cutter with embedded teeth can mill the step surface through its side cutting edge, which can control the height and width of the step

-

22 04 2025

What are the advantages of slotted straight shank end mills

The inserted tooth straight shank end mill has the following advantages: 1.High Cutting Performance Replaceable Inserts: The inserts of the inserted tooth straight shank end mill are replaceable. When the cutting edges of the inserts are worn, only the inserts need to be replaced instead of the entire tool. This not only saves the tool cost but also reduces the downtime caused by tool repl